5 Do’s and Don’ts for Your Next cGMP FDA Inspection

March 19th, 2013 // 2:15 pm @ jmpickett

March 19, 2013

Hot Story – Avoid a CAPA File Inspection Disaster

Our Webinar last week with Dennis Moore on cGMP FDA inspection tips, tricks, disasters and horror stories was really informative (and it’s rebooked for April 11). What I liked the most was his very simple point that FDA investigators are people too. If you make life pleasant for them, they will be more likely to make life pleasant for you. If you make their lives miserable….well, you can guess what is going to happen :).

As Dennis noted in his webinar, you’d THINK some of this would be obvious, but pharma professionals irritate their FDA investigator far too often.

According to Moore, if you want to really irritate your FDA investigator, here’s five things you should do/not do:

#1 Don’t — Stick Your FDAer in the Boiler Room

If your investigator’s work space looks like this, please relocate him or her. You probably wouldn’t like it much if YOU were put in a dank, nasty, hot room with bad light, uncomfortable chairs and bad Internet. And he won’t like it either. Keep your FDAer cozy – give him a nice work space with good light, nice chairs, and good Internet.

#2 Do — Send Grumpy Personnel on a Fishing Trip During the Inspection

Do you have any abrasive and unpleasant people in your facility? Sure, we all do. Make sure that those folks have as little dealings with the FDA investigator as humanly possible. If you can, you might even try to send the nasty one in your office on a little well-earned vacation.

Do you have any abrasive and unpleasant people in your facility? Sure, we all do. Make sure that those folks have as little dealings with the FDA investigator as humanly possible. If you can, you might even try to send the nasty one in your office on a little well-earned vacation.

In our cGMP regulations Webinar, Moore talked about a foreign inspection in Norway he worked on. A mean character in the facility was actually sent on a fishing trip when FDA was in the house. You don’t have to send the grumpy folks on a trip, but try to keep them away from the investigator, please!

#3 Don’t — Injure the FDA Investigator With One of Your Manufacturing Processes

You naturally are going to be walking your FDA investigator through your manufacturing facility. Keep in mind that he or she is not familiar with your day to day operations, and you need to make sure you keep the FDAer safe. Moore noted once that he was on an inspection for FDA in an injection molding facility. The robotics system was operating at the time and he was almost injured.

Make sure that your FDAer is properly escorted!

#4 Don’t — Have The Head Cheese Call Out Sick During the Close Out Meeting

After your FDA inspection, the investigator will hold a close out meeting with your company’s key personnel. Here the FDAer will talk about any observations on the 483, or any other observations the investigator noted. At the meeting you should compare the 483 against your notes from the inspection to make sure everything is accurate.

Also, it is VITAL that top management be at this meeting. According to Moore, the worst thing to do is to have your top guns out of the office that day. It makes a very bad impression. Top management definitely should be on hand at the FDA close out meeting to provide information on any needed corrective actions.

#5 Do — Keep Your SOPs Simple and To the Point for the Investigator

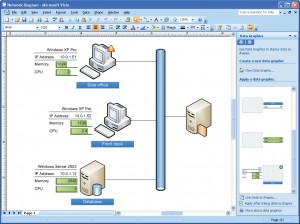

Visio is a great software tool to use during FDA inspections, Moore told us. For example, he recommended that you keep your SOPs nice and simple for FDA because they are not intimately familiar with your processes. A nice, easy Visio map of your key SOPs can really impress FDA.

Moore also said that a nice high level Visio map is useful to guide the investigator during the inspection. If you provide a nice high level road map for her, this will also impress the investigator. By the way, if you don’t provide any road map for the investigator, she might go off in a direction that you may not want. So a nice Visio road map is always a big plus.

Upcoming Expertbriefings.com Webinars 2013

Check out our latest FDA drug and device news, too!

- March 28 – Why You May Want to Move Your Pharma Company to Kansas – 483 and Warning Letter Trends

- April 3 – Audit Your Lab Like an Expert FDA Auditor: A Roadmap to Lab Compliance

- April 10 – Avoid the CDRH eCopy Chaos – How to Prepare a Compliant eCopy Submission

- April 11 – The Quality Manager Gets Fired, the $100,000 Compliance SNAFU, And 21 Tips and Tricks For Your Next Audit

- April 30 – FDA Hands Out CAPA 483s Like Candy – Avoid Them With a Closed Loop CAPA SystemÂ

- May 1 – Avoiding Warning Letter Disasters With a Strong Contractor Quality Agreement